DIFFERENT EFFECT OF SPRAY NOZZLES

In dry fire protection systems, water does not enter the pipes until a remote valve (ie. deluge valve) is activated by a

sensor, making them ideal for outdoor applications, or in places where the system will be exposed to temperatures

when fire incident happens. Nozzle effectiveness in these systems is greatly impacted by the design of spray patterns,

the calculated spray angle, the size of the droplet and the nozzle flow rate. From an efficiency standpoint, the smaller

the size of a droplet, the greater the surface area to volume ratio. The greater ratio translates to faster heat transfer and

faster evaporation and results in energy being removed from the fire faster. Herewith some models have used in 3S-

Firestop' projects in the past.

MEDIUM VELOCITY NOZZLES

Medium Velocity Water Spray Nozzle is an open orifice, directional spray nozzle, designed for use in water spray fixed systems for fire protection applications. MV nozzle comes in various materials of construction. The nozzle is available in brass, stainless steel 316 and aluminium bronze construction. If use Reliable brand, MV Nozzle is UL Listed, FM Approval. The nozzle has an external deflector that discharges a uniformly filled cone of medium velocity water droplets. It comes with option of several k-factors and spray angles and therefore any system designer is able to effectively integrate the nozzle for water spray applications. One versality of using this MV model is 0 o - 180 o free orientation.HIGH VELOCITY NOZZLES

High Velocity Water Spray Nozzle is an open orifice and non-automatic directional spray nozzle. HV nozzle is designed for use in fixed water spray fire protection systems where a high velocity water application is needed. This includes applications such as protection of beam structures, storage tank, loading bay etc. Compared with MV nozzle, this nozzle having higher water kinetic velocity as HV does not have external deflector that will block and disperse the water solid discharge. As per experience, do not use for application like in electrical transformer, circuit breakers or other objects those don't allow water penetration to the interior when direct impingement of water sprayed. HV nozzle comes in brass or stainless steel materials of construction. For non-UL/FM products, use brand 3SAFE .If UL Listed certified & FM Approved, brand is HD Fire. K-factor available K-22 x 75°, K-18 x 80°, K-26 x 100°, K-32 x 90°, K-42 x 115° and K-23 x 120° .Size comes in one choice 3/4" BSP/NPT-Male only.WATER CURTAIN NOZZLES

Spray Pattern of Flat Fan Nozzle

Water Curtain Nozzles (or Fan Flat as the spray pattern is flat) are non-automatic open, outside sprinklers intended for

the protection of windows, walls, steel beams, columns, roofs and any other structures against exposure fire and heat

penetration. Water Curtain nozzles are generally installed with orifice slot pointing downwards direction. The curtain

spray absorbs and reflects heat radiation, minimizing the amount of heat reaching the structure/area to be protected.

The curtain spray absorbs and reflects heat radiation, mini -

mizing the amount of heat reaching the object to be protected.

If need UL Listed certified, brand is HD Fire. HV K-Factors

are K20, K23, K32, K42, K58 and K79. Material can be Brass

or Stainless Steel. Size only one choice 1/2" BSP/NPT-Male.

In the YouTube link below, these nozzles are used to protect

nearby Central Control Room of plant operation as the buiding

just 20 meter away from the plant structures : https://www.youtube.com/watch?v=tD0ks0AQXQY

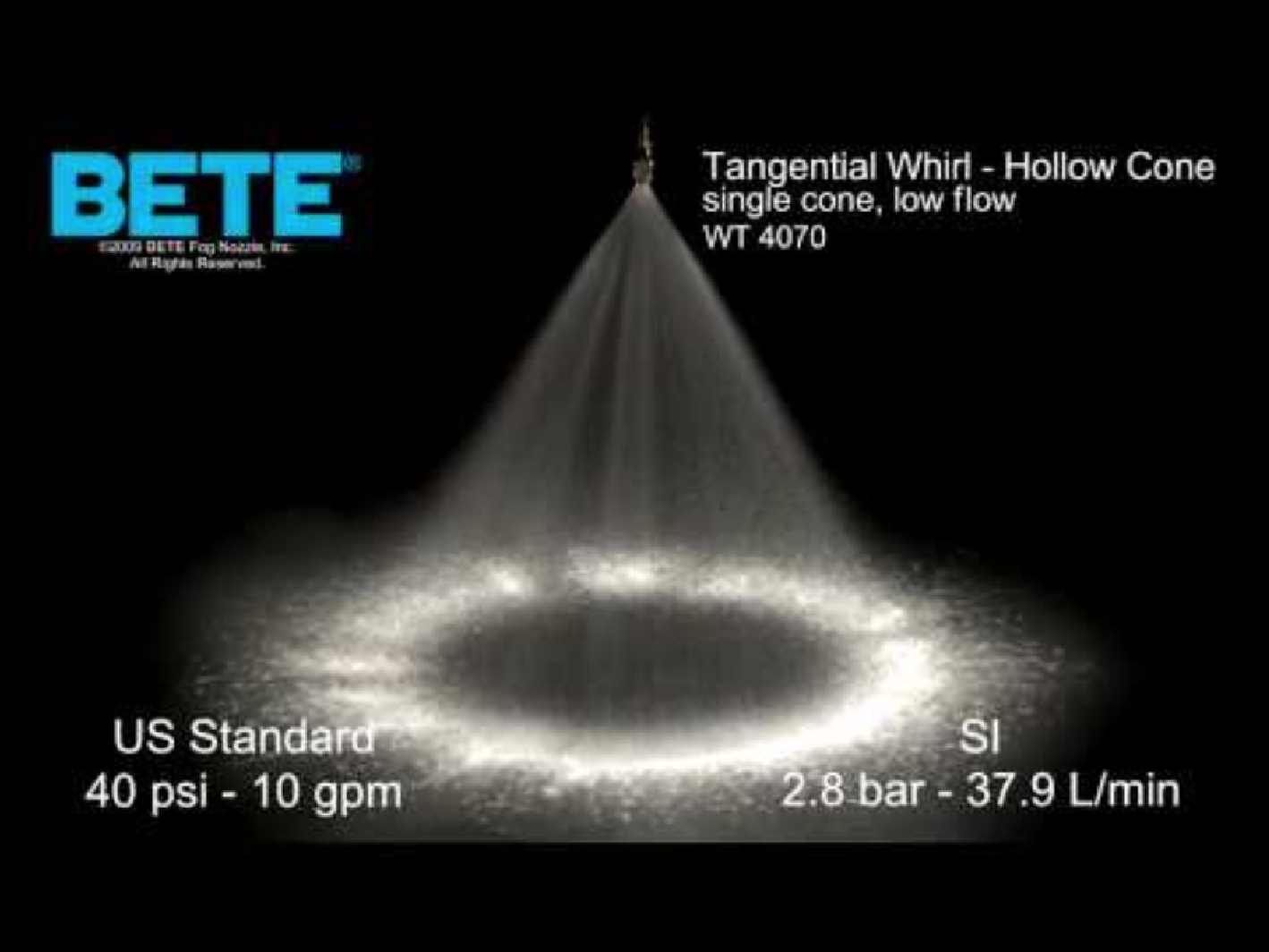

SPIRAL / WHIRL NOZZLES

Spiral nozzle is a kind of full cone or hollow cone nozzle, spray angle range is 60°-170°.Liquid flow rate range is 5.5- 410 L/min. This compact nozzle has design of smooth flow channels which can minimize the block of liquid to make liquid reach max flow in given size pipe. Spiral nozzle can be installed or updated on most piping system. The available nozzle is NPT or BSPT (male) threaded type. Usually 1/4’’-2’’ nozzle can separately use brass, 316 stainless steel casting, teflon. Other material can be used if they are applied to special fields.Conn. Size : 1/4’’; 3/8’’ ; 1/2’’ ; 3/4’’ ; 1’’ ; 1-1/2’’ ; 2’’ ; 3’’ ; 4’’

Spray Pattern : Full Cone / Hollow Cone

Spray Angle : 60° ; 90° ; 120° ; 150° ; 170°

Material : Stainless steel (303,304,316) ; Brass; Plastic (PP, PVDF, PTFE)

As said nozzle effectiveness in these systems is greatly impacted by the size of the droplet and the nozzle flow rate. From an efficiency standpoint, the smaller the size of a droplet, the greater the surface area to volume ratio. The greater ratio translates to faster heat transfer and faster evaporation and results in energy being removed from the fire faster. Anyway the smaller the size of a droplet, it can be easily swept away by the wind and do not reach the targeted object surface. In certain application, a hollow cone whirl nozzle SHALL be applied. The spiral design allows the largest droplets to migrate toward the outside of the pattern, thus providing protection to the smaller droplets allowing them to penetrate the target area (larger droplet will be in outer ring and smaller droplet in the center of the spray ring pattern. For cost effective non-fire protection application uses brand 3SAFE . Anyway as most nozzles used in fire protection application needs UL Listed and FM Approval, use brand BETE Nozzle from USA.

Spiral Nozzle can designed for use in water spray fixed systems for fire protection applications (special hazard application). With free orientation of the installation, Spiral Nozzle can be used for gas scrubbing and dust scrubbing as well like application in coal tunnel. Extinguishing of cable fires in cable trays inside the underground tunnel is also effective as small droplet can easily enter spaces between two vertical trays.

BETE Hollow Cone Spray Pattern

Application example in oil & gas field :

BETE model TF is used for water wall protection system on an oil rig. The purpose of the system is to protect equipment and personnel from the extreme heat generated by the natural gas flare when it was operated. The extreme 150° and 170° spray angles included in the TF series offer the best coverage, but at the cost of atomization.

BETE model TF is used for water wall protection system on an oil rig. The purpose of the system is to protect equipment and personnel from the extreme heat generated by the natural gas flare when it was operated. The extreme 150° and 170° spray angles included in the TF series offer the best coverage, but at the cost of atomization.